When it comes to window screens, there are several common materials used, each with its own set of benefits. One widely used material is aluminum, known for its durability and lightweight properties. Aluminum screens are resistant to rust and corrosion, making them suitable for outdoor use and areas with high moisture levels.

Another popular choice is stainless steel mesh, which offers excellent strength and durability. Stainless steel screens are highly resistant to corrosion, staining, and damage, making them ideal for long-term use in various environments.

However, one material that stands out for its unique advantages is fiberglass. Fiberglass window screens are made from woven strands of fiberglass material coated with a protective PVC layer.

Hiking Screen, as China’s largest window screen supplier, will introduce the characteristics and advantages of the various window screen materials mentioned above, serving as your reference for purchasing window screens. Strength, durability, cost and outward visibility are some of the considerations to keep in mind when choosing mesh material. The right mesh material will depend on which factors matter more to you.

Fiberglass Insect Screen mesh

Fiberglass stands out as a widely used material for insect screens due to its affordability and excellent outward visibility. It is lightweight, flexible, and resistant to corrosion, making it a practical choice for screening needs. HikingScreen further enhances fiberglass’s strength by coating it with PVC.

it’s essential to note that fiberglass does have some drawbacks compared to other mesh materials. It is less durable and more susceptible to tearing or fraying at the edges. Over time, fiberglass screens may also stretch, impacting their effectiveness. Prolonged exposure to strong sunlight can weaken fiberglass screens and may lead to discoloration.

However, PVC coated fiberglass insect screens offer a range of advantages that make them a preferred choice for many applications. The PVC coating enhances durability, providing resistance against tearing, fraying, and stretching, while also protecting the screen from corrosion in diverse weather conditions. These screens are easy to maintain and clean, maintaining their clarity and functionality over time. Despite their enhanced features, PVC coated fiberglass screens remain cost-effective, making them a practical and reliable option for both residential and commercial use.

Fiberglass window screens are popular in many regions, particularly in areas with mild climates and distinct seasons. They are commonly welcomed in locations where extreme weather conditions are not prevalent, as they do not need to withstand harsh environmental challenges. Additionally, fiberglass screens are favored in regions with lower economic conditions due to their relatively low cost. They are commonly found in residential homes, offices, and other general-use settings, offering effective insect protection and transparency. Glass fiber screens are also suitable for areas where good visibility and natural light are essential. Overall, they are popular in regions with mild climates, lower economic conditions, general-use settings, and a need for good visibility and transparency.

Aluminum Wire Mesh

Aluminum window screening is crafted through a meticulous process starting with the preparation of an aluminum rod, which is drawn through a series of dies to reduce it to wire. This wire is then wound onto a master beam and loaded onto a weaving loom where it is woven using a shuttle-fed “fill” wire to complete the horizontal direction of the mesh construction. Post-weaving, the screen fabric undergoes a paint and heat-treated finish to ensure the wires are firmly bonded at their junction points.

Aluminum screening boasts several advantages such as durability, as it can withstand harsh weather conditions and provide excellent ventilation due to its mesh structure. However, it is prone to denting or creasing easier compared to some other materials. Additionally, its cost is relatively higher, which may impact project budgets. These factors should be considered when choosing aluminum window screening for specific applications.

Aluminum window screens are likely to be popular in regions with dry climates, as aluminum’s resistance to oxidation makes it less prone to rust or corrosion in such environments. They may also be favored in areas with relatively good economic conditions, as aluminum screens are generally more affordable compared to high-end materials. Additionally, they are suitable for locations requiring durability, stability, good visibility, and visual appeal, making them a versatile choice for various settings. Overall, aluminum window screens may be welcomed in regions with dry climates, favorable economic conditions, and a need for durability, stability, visibility, and aesthetics.

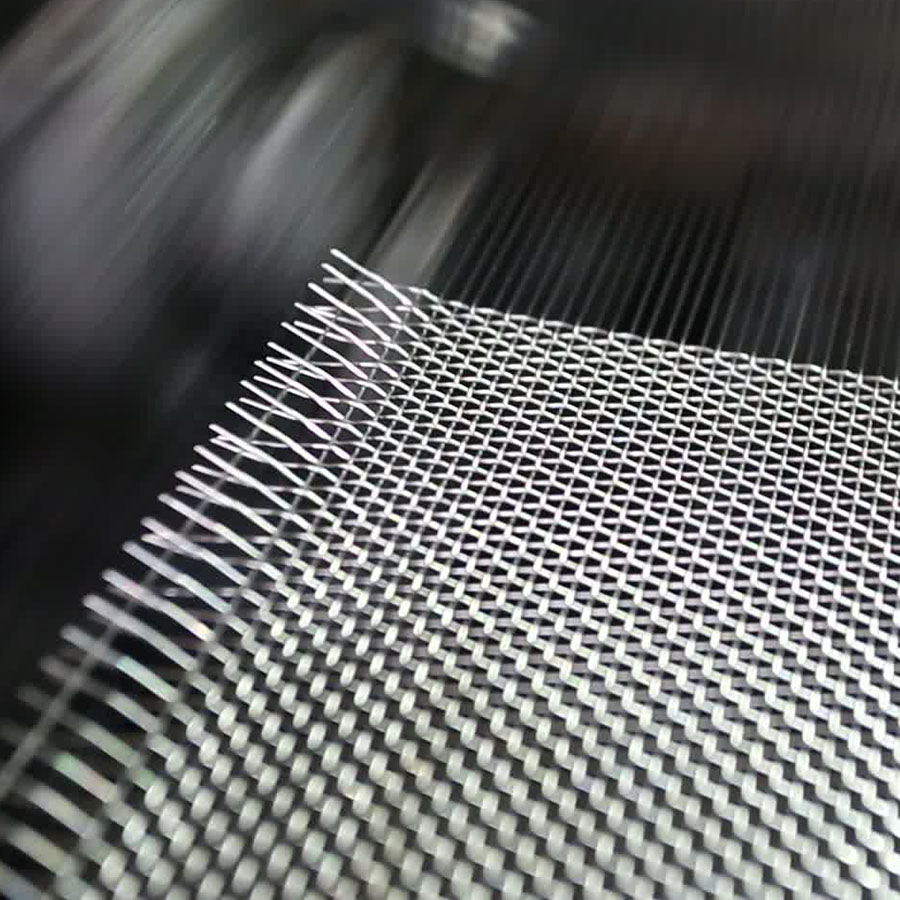

Stainless Steel Mesh

Stainless steel wire cloth is composed of stainless steel wires woven or welded in a square or rectangular grid with tiny openings, creating a screen. Post-weaving, the screen material is often treated with a protective coating to enhance durability and resistance to corrosion. Also called wire mesh or wire fabric, it’s utilized for aesthetic purposes like decorative fencing or window screens and performance reasons such as filtration or ventilation.

Stainless steel window screening offers notable advantages such as exceptional durability and resistance to corrosion, making it suitable for harsh outdoor environments. Its strength also allows for smaller mesh sizes, providing effective insect protection without compromising visibility. However, stainless steel screening can be relatively expensive compared to other materials like aluminum or fiberglass. Additionally, it may require specialized tools or expertise for installation due to its sturdy nature. These factors should be considered when choosing stainless steel window screening for specific applications.

Stainless steel window screens are popular in areas with high humidity or coastal climates due to their excellent corrosion resistance. They are also favored for their durability, making them suitable for frequent window openings in commercial or high-traffic areas. The strong protective properties of stainless steel screens, along with their modern appearance and high-end quality, contribute to their popularity in locations where protection and aesthetics are valued. Overall, stainless steel window screens are welcomed in regions with humid climates, coastal areas, frequent window usage, a need for protective features, or a focus on appearance and quality.